Refractory-grade silicon carbide (SiC) is widely used in high-temperature industrial equipment for its outstanding thermal shock resistance, corrosion resistance, and mechanical strength at elevated temperatures. Whether applied in castables, bricks, kiln furniture, or furnace linings, SiC helps improve durability, run-time stability, and service life under demanding thermal cycling conditions.

This guide explains how refractory SiC works, where it is used, and how to select the right grade for industrial refractory systems.

Introduction

Refractory materials used in cement kilns, steel ladles, reheating furnaces, and industrial ceramics production must withstand extreme temperatures, rapid thermal cycling, abrasion, and chemical attack. Silicon carbide is one of the few raw materials that can maintain structural integrity under all of these conditions.

Unlike traditional alumina-based refractories, SiC provides a unique combination of hardness, thermal conductivity, oxidation resistance, and minimal deformation at high temperature. These characteristics make it valuable both as a primary refractory material and as an additive in monolithic formulations.

In this article, we will discuss how refractory-grade SiC works, common industrial applications, and practical guidelines for selecting the right grade.

1. Key Features of Refractory-Grade Silicon Carbide

Refractory-grade SiC is typically between 85% and 98% purity, depending on the formulation. Its primary performance advantages include:

- High thermal shock resistance – rapid temperature changes cause minimal cracking or distortion.

- Excellent corrosion and slag resistance – especially against alkalis and molten metals.

- High thermal conductivity – reduces thermal gradients and protects surrounding materials.

- Low thermal expansion – enhances dimensional stability.

- High mechanical strength at elevated temperatures – maintains load-bearing performance.

These properties help extend the service life of refractory structures in harsh operating environments.

2. How Silicon Carbide Is Used in Refractory Systems

SiC acts as both a structural material and a performance-enhancing additive. Its roles include:

- Improving thermal shock resistance in castables and ramming mixes.

- Increasing corrosion resistance in areas exposed to slag or metal contact.

- Enhancing thermal conductivity of furnace linings, reducing hot spots.

- Improving wear resistance in high-abrasion zones.

- Reducing oxidation and spalling in cycling environments.

3. Common Grades and Chemical Properties

Refractory SiC generally falls into these main grade categories:

- SiC 90% – commonly used in castables and bulk refractories.

- SiC 92–95% – higher durability and oxidation resistance.

- SiC 97–98% – premium grade for advanced refractories and kiln furniture.

Particle size can range from coarse fractions (3–5 mm) to fine powders (<200 mesh), depending on the mix design.

SiC 90% – commonly used in castables and general refractory mixes.

SiC 95% – improved durability and oxidation resistance in demanding zones.

SiC 97–98% – premium grade for kiln furniture and high-performance refractories.

4. Forms of Silicon Carbide Used in Refractories

SiC is used in refractory production in several physical forms:

- Crushed grains – for bricks, castables, and kiln components.

- Powders – used as additive or filler to improve bond structure.

- Manufactured shapes – saggers, beams, kiln furniture components.

The form selected depends on design requirements and processing method.

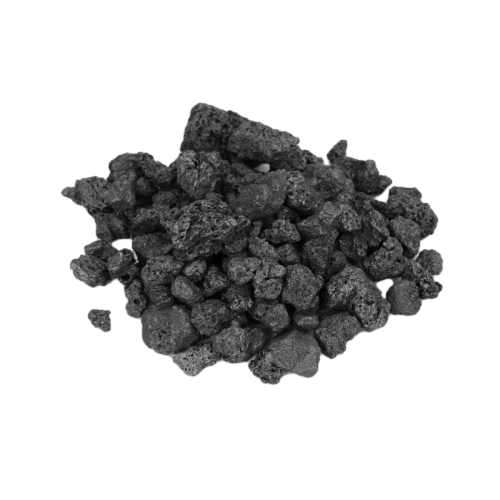

Typical refractory-grade SiC granules and powders used in castables and brick formulations.

5. High-Temperature Industrial Applications

Refractory-grade silicon carbide is commonly used in:

- Steel industry: tap holes, troughs, ladles, and slag-contact zones.

- Foundries: furnace linings and molten metal contact areas.

- Ceramic kilns: kiln furniture, beams, plates, and setter tiles.

- Non-ferrous industries: aluminum and copper furnaces.

- Cement plants: preheater, cooler, and transition zones.

- High-temperature reactors: chemically aggressive environments.

Its resistance to corrosion and thermal shock makes SiC especially valuable in areas where traditional refractories degrade quickly.

6. How to Select the Right SiC for Refractory Formulations

Selection depends on:

- Operating temperature – higher temperatures benefit from higher-purity SiC.

- Exposure environment – slag, alkalis, and molten metals require corrosion-resistant grades.

- Mechanical load – load-bearing zones may require larger SiC fractions.

- Thermal cycling frequency – rapid changes favor SiC-rich formulations.

- Mix design – powders vs. coarse grains depending on castable or brick production.

7. Information to Share When Requesting a Quote

Providing clear details ensures an accurate recommendation. Useful information includes:

- Target application (kiln furniture, castable, furnace lining, etc.)

- Operating temperature range

- Expected chemical exposure (slag, alkali, metal)

- Desired particle size or grading

- Annual consumption volume

8. FAQ

Q1: What purity is considered “refractory grade” silicon carbide?

Refractory-grade SiC typically ranges from 90% to 98% purity depending on the application and performance requirements.

Q2: Why is SiC used in castables and monolithic refractories?

It significantly improves thermal shock resistance, corrosion resistance, and structural stability at high temperature.

Q3: Does SiC oxidize at high temperature?

Yes, but it forms a protective silica layer that slows further oxidation. High-purity grades resist oxidation better.

Q4: Can silicon carbide be used in direct-contact metal zones?

Yes. Its corrosion resistance makes it suitable for slag-contact and molten-metal environments in steel and foundry industries.

Q5: What particle size should be used?

The optimal size depends on mix design: coarse grains for structural strength, fine powders for bonding and density control.

9. Request Material Recommendations

If you need refractory-grade silicon carbide for castables, bricks, or kiln components, our team can recommend suitable grades and particle sizes based on your application.

WhatsApp: +86-17803859504

Website: https://canabrasive.com