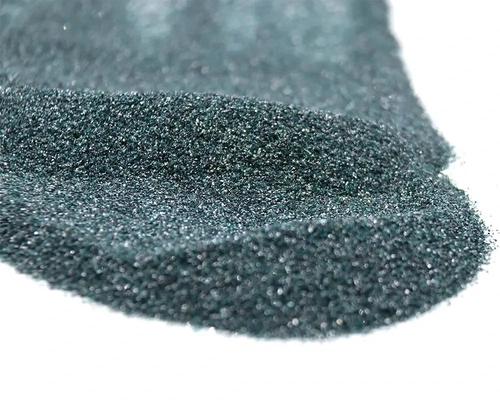

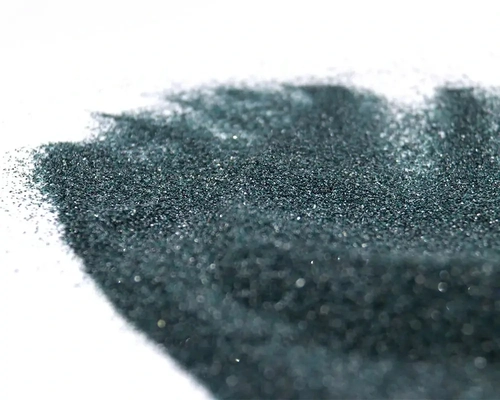

Green silicon carbide is valued for its high hardness, sharp crystalline structure, and relatively high purity. What really determines its behavior in practice, however, is not only the chemistry but also the grit size. From coarse grains used in aggressive stock removal to ultra-fine micro powders for mirror polishing, each size range serves a distinct role in the process chain.

This guide walks through the typical applications of green SiC from coarse grits to micro powders, helping engineers, process developers, and buyers match the right size range to their specific substrates and finishing requirements.

Introduction

In precision manufacturing, abrasive selection is rarely a matter of material alone. Once the decision has been made to work with silicon carbide, the next critical step is choosing an appropriate grit size for each stage of machining or finishing. This is particularly true for green SiC, which is often used where surface quality and dimensional control are important.

The same material behaves very differently as a coarse F24 grain compared with an F800 micro powder. One will quickly remove material and shape the part; the other will refine the surface and reduce roughness to a level suitable for sealing, bonding, or optical performance. Understanding these differences allows you to design clearer process windows and avoid over- or under-specification.

The sections below group green silicon carbide into practical size ranges and discuss where each range tends to be used: coarse grinding, intermediate honing, fine lapping, and high-end polishing.

1. Overview of Green Silicon Carbide

Green silicon carbide is produced in an electric resistance furnace from high-purity silica and a carbon source. Compared with the black variant, it generally offers:

- Higher overall purity

- Sharper, more brittle crystalline structure

- Higher hardness (around Mohs 9.5)

These characteristics make it especially useful in applications where the workpiece is hard, brittle, or sensitive to contamination: advanced ceramics, glass, hard alloys, and certain composite materials.

2. How Grit Sizes Are Classified (F-Series Overview)

In many industrial contexts, grit sizes are described using the FEPA F-series (F12, F16, …, F1200). While the exact particle size distribution is defined by standard tables, the practical viewpoint is:

- Smaller F-number → coarser grain → higher material removal, rougher finish

- Larger F-number → finer grain → lower removal rate, smoother finish

In this article, we will use approximate groupings—coarse, medium, fine, and micro powders—to discuss application trends, rather than focusing on the detailed numeric limits of each standard.

3. Coarse Grits (Approx. F12–F60): Shaping and Heavy Grinding

Coarse green SiC grains are used where the primary goal is fast stock removal or shaping of very hard materials. Typical uses include:

- Rough grinding of technical ceramics and hard alloys

- Forming operations on carbide tools before finer finishing steps

- Heavy-duty surface conditioning where high cutting power is needed

At this stage, the focus is not on final surface quality. Instead, these grits are chosen for their ability to remove material quickly while maintaining acceptable load on the machine and tooling.

4. Medium Grits (Approx. F80–F220): General Precision Grinding

Medium-size grains bridge the gap between rough shaping and fine surface preparation. They are often used in:

- Grinding operations where dimensional tolerances are already close to final values

- Intermediary steps between coarse grinding and lapping

- Edge preparation for tools and components that require defined surface topography

In many process chains, these grits are responsible for eliminating the deeper scratches left by coarse tools, while still maintaining a reasonable removal rate.

5. Fine Grits (Approx. F230–F400): Pre-Polishing and Fine Lapping

Fine green SiC grits move the process into the pre-polishing or fine lapping region. Common applications include:

- Preparing ceramic and glass surfaces for subsequent micro powder polishing

- Fine lapping of hard seals, valve components, and precision mechanical parts

- Intermediate finishing of carbide tools before final hone or polish

At these sizes, the material removal per pass is lower, but the scratch pattern becomes more uniform and shallow. Choosing the right grit in this range helps minimize the number of subsequent polishing steps required.

6. Micro Powders (Approx. F500–F1200+): High-End Polishing

Micro powders are where green silicon carbide shows its value in high-end finishing. These very fine grades are typically used in:

- Polishing of advanced ceramics and hard alloys where low Ra values are required

- Surface finishing of optical components and specialty glass products

- Precision lapping where tight flatness and sealing performance are critical

- Process steps that prepare surfaces for coatings, bonding, or further functionalization

Here, particle size distribution and the absence of oversized particles become especially critical. Even a small amount of coarse contamination can leave visible scratches on otherwise well-polished surfaces.

7. Application Matrix by Grit Size and Substrate

The table below summarizes how different size ranges are commonly aligned with materials and process stages. Exact choices depend on machine type, coolant, and individual quality targets, but the matrix offers a useful starting point for discussions with production teams and suppliers.

| Grit Range (Approx.) | Typical Use | Representative Substrates |

|---|---|---|

| F12–F60 (coarse) | Rough grinding and shaping | Technical ceramics, hard alloys, wear parts |

| F80–F220 (medium) | General precision grinding | Ceramic components, carbide tools, glass edges |

| F230–F400 (fine) | Pre-polishing and fine lapping | Mechanical seals, valve surfaces, precision parts |

| F500–F800 (micro) | Intermediate polishing steps | Advanced ceramics, high-performance metals |

| F1000–F1200+ (micro) | Final polishing and surface refinement | Optical glass, hard alloys, sealing faces |

8. Practical Tips for Selecting Grit Sizes

When planning a process sequence with green SiC, it is often helpful to work backwards from the required surface quality and dimensional tolerances:

- Start by defining the final roughness and flatness requirements.

- Choose micro powder grades that can realistically achieve that finish.

- Then work upstream to select fine and medium grits that remove the previous scratch pattern efficiently.

- Reserve coarse grits for situations where large material corrections are needed.

In practice, many plants refine their grit choices over time based on experience, test panels, and feedback from downstream processes such as coating, sealing, or assembly.

9. Information to Share with Your Supplier

To receive useful guidance on grit selection and grain specification, it helps to share more than just the F-number. Information that typically improves recommendations includes:

- Type of material being processed (ceramic, glass, carbide, metal)

- Process type (grinding, lapping, polishing, blasting)

- Target surface roughness or functional requirement

- Machine type and coolant conditions

- Whether the material is for loose abrasive, bonded tool, or coated product

With these details, a supplier can suggest not only the nominal grit size but also suitable PSD ranges and purity levels.

10. FAQ

Q1: Why choose green silicon carbide instead of black for fine grits?

Green grades offer higher purity and a more brittle crystal structure, which tends to produce sharper cutting edges and cleaner scratch patterns in fine grinding and polishing.

Q2: How many grit steps are normally used from rough grinding to final polish?

The number of steps depends on the starting surface and final requirement. Some processes use three or four stages, while demanding optical or sealing surfaces may require more intermediate transitions.

Q3: Can the same grit size be used for both ceramics and glass?

Sometimes yes, but optimal choices often differ. Ceramics and glass respond differently to pressure and cooling conditions, so it is worth testing and adjusting grit sizes for each substrate.

Q4: Are micro powders only used in slurry form?

They are commonly used in slurries and compounds, but can also be part of bonded or coated systems where very fine surface finishes are required.

Q5: What should I monitor when switching to a different grit size?

Key observations include removal rate, temperature development in the contact zone, scratch pattern, and any impact on downstream process steps. It is also useful to check tool wear and overall stability over a full batch.

11. Request Grit Recommendations

If you are planning a new grinding or polishing sequence with green silicon carbide or reviewing an existing process, our team can help compare grit options and discuss suitable grain specifications.

WhatsApp: +86-17803859504

Website: https://canabrasive.com