Abrasive Materials Insights: BFA, WFA & Silicon Carbide

Read technical articles and sourcing advice on Brown Fused Alumina, White Fused Alumina, and Silicon Carbide. Learn about their grit standards, industrial uses, and supplier evaluation tips.

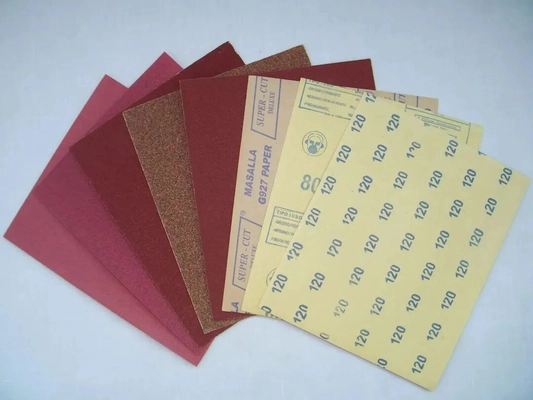

Silicon Carbide Powder: Grit Sizes, Uses & Price Guide

Read More

What Is Carborundum Used For?

Read More

Best Abrasives for Sandblasting and Surface Preparation: Silicon Carbide and More

Read More

The Role of Silicon Carbide in Abrasive Manufacturing

Read More

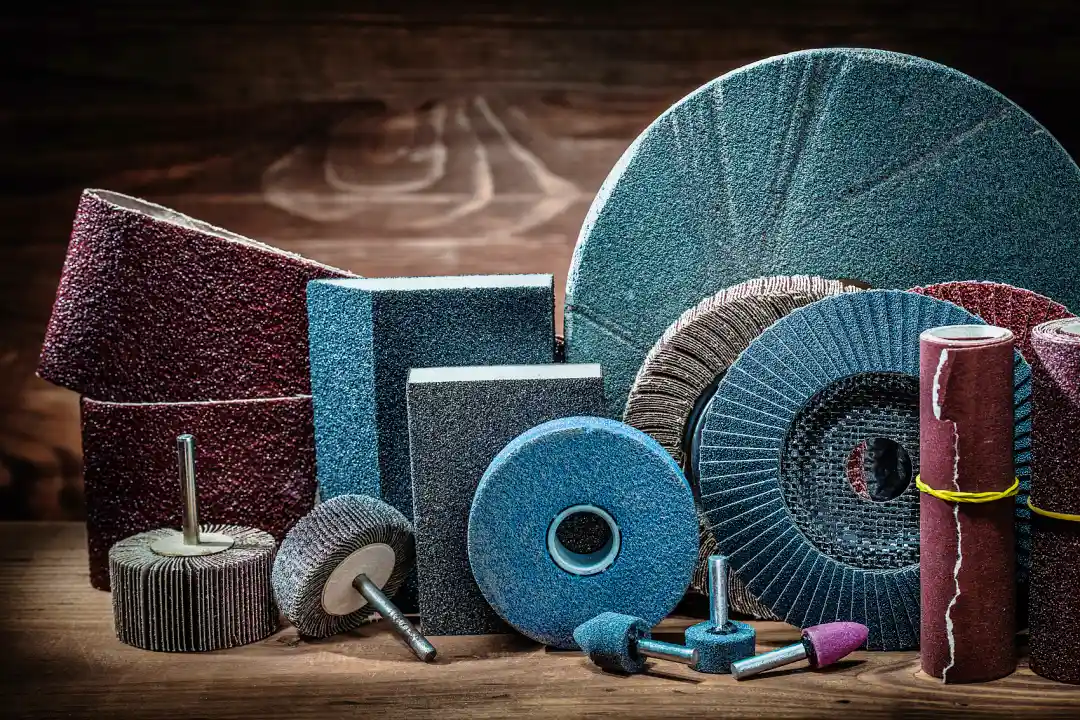

How to Choose the Right Abrasive for Your Grinding and Polishing Needs

Read More