Quick Answer

Quick Answer: Silicon carbide (SiC) abrasives are extremely hard, sharp-edged materials used for grinding, blasting, and polishing metals, ceramics, glass, and refractories. With a Mohs hardness of about 9.2 – 9.4 and high thermal stability, SiC offers superior cutting power and longevity compared to aluminum oxide. Its two main forms—black and green—differ in purity and friability: black SiC is tough and cost-effective for general blasting, while green SiC is purer and sharper for precision finishing and lapping applications.

Table of Contents

- 1. Overview of Silicon Carbide Abrasives

- 2. Physical and Chemical Properties

- 3. Types of Silicon Carbide Abrasives

- 4. Mechanics of Cutting and Grinding (with formulas)

- 5. Industrial Applications

- 6. Comparison: SiC vs Alumina vs Ceramic Alumina

- 7. Selection Guide by Process and Material

- 8. FAQ

1. Overview of Silicon Carbide Abrasives

Silicon carbide is a compound of silicon (Si) and carbon (C) formed by high-temperature electrofusion. It combines exceptional hardness, chemical inertness, and high thermal conductivity. Because SiC crystals fracture easily under stress, fresh sharp edges are continually exposed—an essential characteristic for high-efficiency material removal. SiC is second only to diamond and cubic boron nitride (CBN) in hardness among common abrasives.

2. Physical and Chemical Properties

| Property | Typical Value | Significance |

|---|---|---|

| Chemical Formula | SiC | Compound of silicon and carbon |

| Crystal Structure | Hexagonal (α-SiC), Cubic (β-SiC) | Affects fracture and friability |

| Mohs Hardness | 9.2 – 9.4 | Extremely hard cutting edges |

| Vickers Hardness (HV) | ≈ 2500 – 2800 | Superior to alumina |

| True Density | ≈ 3.21 g/cm³ | Influences momentum and impact energy |

| Thermal Conductivity | ≈ 120 – 200 W/m·K | Rapid heat dissipation during grinding |

| Electrical Resistivity | 10⁴ – 10⁶ Ω·cm | Suitable for semiconductive applications |

| Chemical Resistance | Excellent to acid/alkali (up to 1500 °C) | Long service life in aggressive environments |

3. Types of Silicon Carbide Abrasives

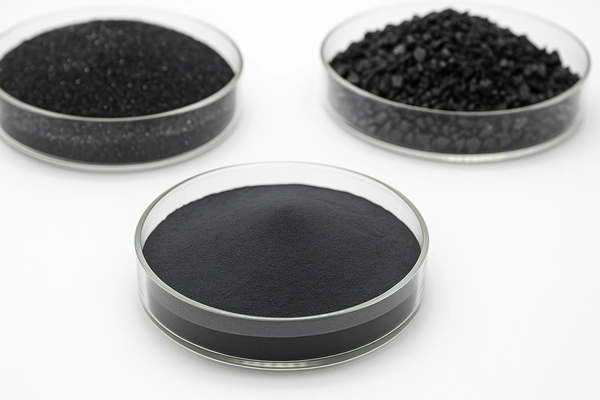

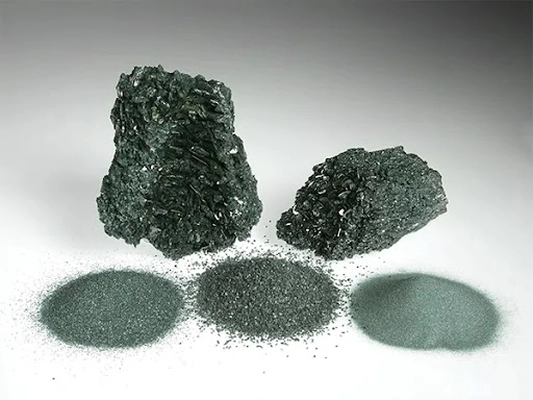

- Black Silicon Carbide (BSiC) – contains about 98–99 % SiC, with impurities of Fe, Al, or Si. Tough and economical; used for metal grinding, blasting, and refractories.

- Green Silicon Carbide (GSiC) – up to 99.9 % purity, more friable and sharper; ideal for precision lapping and ceramic polishing applications.

- Micro-powder Grades – sub-micron SiC used for superfine lapping and optical polishing where Ra < 0.02 μm is required.

4. Mechanics of Cutting and Grinding (with formulas)

The cutting and polishing behavior of SiC depends on particle energy, contact pressure, and relative velocity. Two basic relations govern the process:

4.1 Impact Energy and Momentum

For a particle of mass m and velocity v:

E = ½ m v² p = m v

For spherical particles of diameter d and density ρ:

m = (π/6) ρ d³ ⇒ E = (π/12) ρ d³ v²

Because SiC has a high density (≈ 3.2 g/cm³), it delivers significant momentum even at moderate particle sizes — resulting in efficient material removal during air-blast or wheel impact processes.

4.2 Preston’s Equation (for grinding and lapping rate)

Material Removal Rate (MRR) is empirically related to pressure and velocity:

MRR = k · P · V

where k is the Preston coefficient (dependent on abrasive type, coolant, and surface chemistry), P is applied pressure, and V is relative speed. For SiC, k ranges from 1×10⁻⁴ to 5×10⁻⁴ mm³/(N·m) depending on grain shape and binder. Increasing pressure or velocity raises MRR linearly until thermal damage or tool wear limits are reached.

5. Industrial Applications

- Grinding and Sharpening: Bonded SiC grains are used in grinding wheels for cast iron, cemented carbide, and hard non-ferrous metals.

- Abrasive Blasting: SiC grit (F24 – F220) delivers high cutting efficiency and sharp surface profiles for coating preparation and composite tool cleaning.

- Lapping and Polishing: Fine SiC micro-powders (F400 – F2000) produce controlled surface roughness on ceramics, optical glass, and mechanical seals.

- Refractories: Coarse SiC aggregates enhance thermal shock resistance and wear strength in bricks, castables, and kiln furniture.

- Semiconductor Processing: SiC slurries are used for wafer slicing and CMP of hard substrates like sapphire and SiC itself.

6. Comparison: SiC vs Alumina vs Ceramic Alumina

| Parameter | Silicon Carbide (SiC) | Fused Alumina (Al₂O₃) | Ceramic Alumina (CA) |

|---|---|---|---|

| Mohs Hardness | 9.2–9.4 | ≈ 9 | ≈ 9.2 |

| Vickers Hardness (HV) | 2500–2800 | 1800–2000 | 2200–2400 |

| Density (g/cm³) | 3.2 | 3.9 | 3.9 |

| Thermal Conductivity (W/m·K) | 120–200 | 30 | 35 |

| Friability | High (continuous self-sharpening) | Medium | Controlled micro-fracture |

| Cutting Aggressiveness | Very high | Moderate | Balanced with longevity |

| Recyclability in Blasting | Low–Medium | Low | Medium |

| Best For | Hard non-ferrous, ceramics, glass | Steel and general purpose | High-pressure precision grinding |

Interpretation: SiC removes material rapidly but wears faster than ceramic alumina. In fine grits or micro-powders, SiC offers outstanding surface finish on brittle materials such as glass and ceramics.

7. Selection Guide by Process and Material

- Material Hardness: The workpiece should be softer than SiC; use SiC for cast iron, carbide, ceramics, glass, and non-ferrous metals.

- Desired Surface Roughness (Ra): Coarse grits (F24–F80) for rough cutting, medium (F100–F220) for finishing, fine (F400+) for lapping/polish.

- Processing Type: Pressure blast → coarse grit; wet lapping → micro-powder; bonded wheel → F24–F120.

- Cost vs Durability: For mass blasting choose black SiC (low cost); for precision optics use green SiC (high purity).

- Safety & Environment: SiC dust is chemically inert but respirable; use dust extraction and PPE.

8. FAQ

Q1: What makes silicon carbide an effective abrasive?

Its extremely high hardness and brittle fracture behavior create continuously sharp edges, ensuring high removal rates and clean cuts on hard materials.

Q2: What is the difference between black and green silicon carbide?

Black SiC is tougher and more cost-effective for blasting and general grinding. Green SiC is purer (≈ 99.9 %) and friable, suitable for precision lapping and polishing.

Q3: Can SiC be used for steel grinding?

It can, but SiC reacts with iron at high temperature, so it is not ideal for hardened steel. Alumina or ceramic alumina is preferred for ferrous metals.

Q4: How is the grain size classified?

By FEPA F-grade system (F24–F2000) or JIS standards. Lower numbers = coarser grains = higher removal rate; higher numbers = finer finish.

Q5: What is the Preston equation used for?

It relates material removal rate to pressure and velocity (MRR = k · P · V). It helps engineers optimize grinding and lapping parameters to balance rate and finish.

Q6: Is silicon carbide recyclable in blasting systems?

Yes, to a limited extent (typically 5–10 cycles) if reclaimed and sieved to remove fines. However, it fractures quickly and is less reusable than steel media.

Q7: What are typical safety precautions?

Use respirators, dust collection, and eye protection. Avoid inhalation of fine dust and store materials in dry areas to prevent agglomeration.

Q8: How does SiC compare to diamond and CBN?

Diamond and CBN are harder but costlier. SiC offers excellent performance-to-cost ratio for non-ferrous and ceramic materials where super-abrasives are unnecessary.