Quick Answer

The best abrasive for a job depends on hardness (cutting ability), density (impact energy), particle shape (aggressiveness), size distribution (finish and rate), and recyclability (cost and cleanliness). For fast stock removal and sharp finishes, high-hardness, angular media such as silicon carbide or fused alumina excel; for surface conditioning, cleaning, or peening with minimal substrate damage, spherical media (glass beads, cast steel shot) provide controlled impact and smoother profiles. Garnet balances cost, cleanliness, and performance for general blasting; plastic media serves delicate substrates; steel grit/shot dominates in heavy-duty facilities thanks to durability and recirculation. Selecting media starts by defining the substrate, target surface profile/roughness, contamination limits, and equipment constraints (pressure, wheel speed, reclaim system), then matching a media whose properties meet those constraints.

Table of Contents

- 1. Abrasive Fundamentals

- 2. Mechanics of Blasting and Polishing (with formulas)

- 3. Common Abrasive Materials

- 4. Property Comparison Table (Mohs, Vickers, Density, Shape, Reuse)

- 5. Application Matrix (Cleaning / Finishing / Polishing / Peening / Deburring)

- 6. Selection Guide: From Spec to Media

- 7. Process Parameters: Size, Velocity, Angle, and Coverage

- 8. Quality, Cleanliness, and Metrology

- 9. FAQ

1. Abrasive Fundamentals

Blasting accelerates particles (air/pressure blast, wheel blast) to erode, clean, or profile a surface. Polishing uses finer abrasives and controlled pressure to reduce roughness and produce gloss. Both are governed by the same material interactions: harder, sharper particles cut more aggressively; denser particles carry more momentum; larger particles increase removal rate but raise roughness; narrower distributions and smoother shapes improve finish but reduce cut.

Key properties to understand:

- Hardness (Mohs, Vickers HV): Resistance to scratching/indentation—drives cutting ability.

- Density (ρ): Affects mass at given size, thus impact momentum/energy.

- Particle shape: Angular (rapid cut, higher Ra) vs spherical (gentler peening/cleaning, lower Ra).

- Friability: Tendency to fracture and self-sharpen; high friability boosts cut but increases dust.

- Size & PSD: Coarse sizes remove faster but yield rougher profiles; microgrits polish to low Ra.

- Recyclability: Steel shot/grit and glass/ceramic beads are highly reusable; single-use media reduce cross-contamination but raise media cost.

2. Mechanics of Blasting and Polishing (with formulas)

At the particle level, impact and plowing remove material. Useful engineering relations:

2.1 Impact energy and momentum

For a particle of mass m and velocity v:

Impact Energy E = ½ m v² Momentum p = m v

At equal size, denser media carry higher m, increasing both energy and momentum. For spherical particles of diameter d and material density ρ:

m = (π/6) ρ d³ ⇒ E = (π/12) ρ d³ v²

2.2 Energy flux to the surface

If the mass flow rate of media is ṁ (kg/s), the energy flux (W) delivered is approximately:

P ≈ ½ ṁ v²

Higher v contributes quadratically, so small increases in velocity may substantially increase cut (but also wear and dust).

2.3 Contact and finish tendencies

Angular particles create micro-plowing; spherical particles cause peening/elastic-plastic deformation. A rule of thumb for finish: for comparable materials and setups, Ra scales roughly with median size and particle angularity. Finer, less angular media achieve lower Ra at the expense of rate.

3. Common Abrasive Materials

Below are the most widely used media for blasting and polishing. Values represent typical ranges (actual specifications vary by supplier, grade, and manufacturing route):

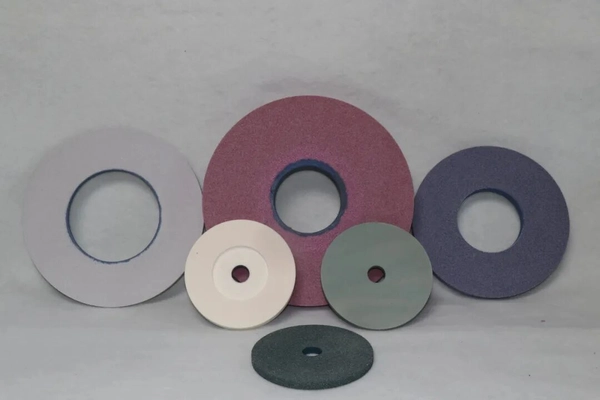

- Silicon carbide (SiC): Very hard, sharp, angular; excellent for rapid cutting, lapping, and fine polishing. High density vs alumina; high friability enables self-sharpening.

- Alumina (Al2O3): Fused alumina is hard, durable, versatile; white fused is purer and sharper for polishing; brown fused is tougher and economical for blasting.

- Garnet: Natural mineral, sub-angular; clean cutting with lower dust than slags; popular for coating removal and general surface prep.

- Glass beads: Spherical soda-lime or specialty glass; gentle cleaning, satin finishes, and cosmetic uniformity; low embedding tendency on many metals.

- Steel shot / steel grit: Cast or atomized steel; very high recyclability in wheel blast systems; shot (spherical) for peening and cleaning; grit (angular) for profiling.

- Plastic media: Urea, melamine, acrylic; low hardness—suited to composites, aluminum, and paint removal without base metal damage.

- Walnut shell / corn cob: Organic, soft; delicate cleaning, historical restoration, aerospace masking applications.

- Ceramic beads: Zirconia-based spheres; high density, excellent recyclability; produce low roughness at moderate rate.

4. Property Comparison Table (Indicative)

Note: Ranges below are indicative and for educational comparison only. Always consult supplier TDS/COA for the exact grade.

| Abrasive | Mohs | Vickers (HV) | Density (g/cm³) | Typical Shape | Friability | Recyclability | Typical Size Ranges | Notes |

|---|---|---|---|---|---|---|---|---|

| Silicon Carbide | 9.2–9.4 | ≈2500–2800 | ≈3.2 | Angular | Medium–High | Low–Medium | F8–F2000; microns | Fast cutting, fine finishes in lapping/polishing |

| Fused Alumina (Al₂O₃) | ≈9 | ≈1800–2000 | ≈3.9 | Angular/Blocky | Medium | Low–Medium | F12–F1200; microns | Versatile; white for purity, brown for toughness |

| Garnet | ≈7–7.5 | ≈1300–1500 | ≈3.9–4.1 | Sub-angular | Low–Medium | Low–Medium | 12–200 mesh | Clean blasting, common in waterjet and dry blast |

| Glass Beads | ≈6 | ≈500–600 | ≈2.5 | Spherical | Very Low | Medium–High | 50–850 μm | Satin finish, low embedding, cosmetic uniformity |

| Steel Shot | ≈4–5 | ≈400–700 (tempered) | ≈7.4–7.8 | Spherical | Very Low | Very High | S70–S780 | Wheel blast, peening, heavy cleaning |

| Steel Grit | ≈4–5 | ≈400–700 | ≈7.4–7.8 | Angular | Low | Very High | G10–G80 | Surface profiling prior to coating |

| Plastic Media | ≈3–4 | ≈25–60 (Knoop/Vickers equiv.) | ≈1.2–1.5 | Angular | Low | Low–Medium | 12–60 mesh | Paint/coat removal on soft substrates |

| Walnut Shell | ≈3–4 | ≈20–40 (equiv.) | ≈1.2 | Angular/Irregular | Low | Low | 8–60 mesh | Gentle cleaning; minimal base-metal removal |

| Ceramic Beads | ≈7–8 | ≈1200–1600 | ≈3.7–6.0 (grade-dependent) | Spherical | Very Low | High | 50–600 μm | Low Ra finishes with strong durability |

5. Application Matrix

The matrix below summarizes typical suitability. “✓✓” = primary fit, “✓” = workable with proper parameters, “–” = generally not recommended.

| Abrasive | Cleaning | Finishing | Polishing | Peening | Deburring |

|---|---|---|---|---|---|

| Silicon Carbide | ✓ | ✓✓ | ✓✓ (microgrits) | – | ✓ |

| Fused Alumina | ✓✓ | ✓✓ | ✓ (fine grades) | – | ✓✓ |

| Garnet | ✓✓ | ✓ | – | – | ✓ |

| Glass Beads | ✓✓ | ✓✓ (satin) | ✓ (very fine) | ✓ | ✓ |

| Steel Shot | ✓✓ | ✓ | – | ✓✓ | ✓ |

| Steel Grit | ✓✓ | ✓ | – | – | ✓✓ |

| Plastic Media | ✓ | ✓ (delicate) | – | – | ✓ |

| Walnut Shell | ✓ (gentle) | ✓ (cosmetic) | – | – | – |

| Ceramic Beads | ✓✓ | ✓✓ (low Ra) | ✓ (fine) | ✓ | ✓ |

6. Selection Guide: From Spec to Media

- Define the substrate: hardness (HV), heat sensitivity, susceptibility to embedding/contamination.

- Define the goal: rust/scale removal, paint stripping, uniform satin finish, pre-coat profile (e.g., 50–100 μm), or low-Ra polishing (e.g., <0.2 μm).

- Set constraints: allowable dust, system type (pressure, suction, wheel), reclaim capability, ventilation/filtration.

- Choose a media family: angular (fast cut/profile) vs spherical (low Ra/peening/cleaning).

- Pick size & PSD: start with vendor’s recommended band for your target finish; narrower PSD for tighter Ra.

- Tune velocity and angle: increase v to raise rate (½ ṁ v²), set ~60–90° for aggressive cut or ~30–60° for gentler cleaning, depending on substrate.

- Verify by coupons: short trials on representative samples; measure Ra/Rz, coverage, salt contamination, and coating adhesion as relevant.

7. Process Parameters: Size, Velocity, Angle, and Coverage

- Particle size: Coarse grit (e.g., 16–36 mesh) produces heavy profiles and rapid removal; mid sizes (60–120) balance cut/finish; fine (180–400, microns) for satin/polish.

- Velocity: Raising pressure or wheel speed increases v and energy (∝ v²), but also media/hood wear and dust—optimize, don’t simply maximize.

- Nozzle/impeller design: Long Venturi nozzles produce higher velocities; wheel blast impeller settings adjust flow focus and coverage.

- Standoff and angle: Closer standoff magnifies intensity; angle influences cut vs peen behavior.

- Coverage & dwell: For uniform finishes, maintain constant traverse and overlap; for peening, satisfy coverage % and intensity via Almen strips.

8. Quality, Cleanliness, and Metrology

Quality depends on media cleanliness, stability, and measurement discipline:

- Cleanliness: Use magnetic separation and sieving; purge fines; avoid oil/water contamination.

- Monitoring: Track PSD drift, spent media %, and dust loading; replace media based on cut rate and finish metrics.

- Metrology: Measure Ra/Rz by stylus or optical profilometry; for coatings, verify anchor profile (e.g., replica tape) and adhesion (pull-off tests).

- Compliance: Observe safety (respirable dust, PPE), disposal regulations, and, for peening, process control standards.

9. FAQ

Q1: Which abrasive removes coatings fastest without excessive roughness?

Angular alumina or steel grit at moderate size often delivers the best rate/profile balance. Garnet is a lower-dust alternative for field work. Fine silicon carbide excels when a sharper, but still controlled, finish is needed.

Q2: How do I minimize surface embedding?

Use spherical media (glass/ceramic beads or steel shot), reduce velocity and angle, dry the air stream, and ensure clean, oil-free media. Hard substrates are less prone to embedding than soft alloys or polymers.

Q3: What determines whether blasting yields a matte or satin finish?

Particle shape (spherical → satin), size (finer → smoother), and velocity (lower → gentler). Glass or ceramic beads with fine grades commonly produce uniform satin finishes.

Q4: Can I use the same media for blasting and polishing?

Sometimes. Silicon carbide and alumina span from coarse blasting grits to micron polishing powders, but the required equipment and dust control differ. In practice, facilities separate blasting from precision polishing lines.

Q5: Why is steel media so popular in production lines?

Because steel shot/grit is extremely recyclable in wheel-blast systems, offering low cost per cycle and consistent performance with proper classification and dust control.

Q6: Is higher hardness always better?

No. Higher hardness raises cut but can overshoot the finish target, increase substrate damage, and generate more fines. Choose hardness to match your substrate and finish specification.

Q7: How do I relate Mohs to Vickers?

They measure different phenomena; there is no exact conversion. Roughly, Mohs 9–9.5 corresponds to HV ≈ 1800–3000 for common ceramics; always consult actual HV data from the media’s technical sheet.

Q8: What formula helps estimate the impact intensity?

A useful first look is energy flux P ≈ ½ ṁ v². For a given mass flow, increasing velocity has a squared effect; however, nozzle wear and dust also grow, so optimize rather than maximize.