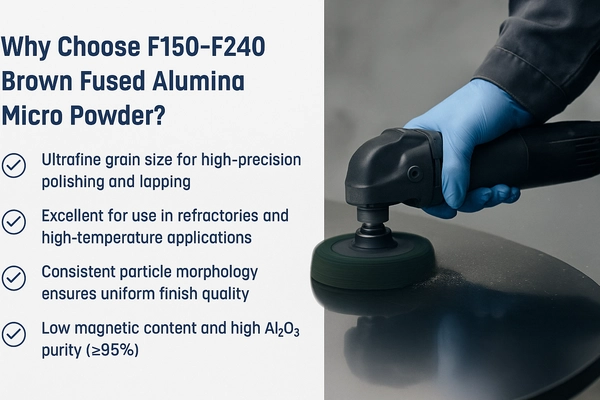

Brown Fused Alumina Micro Powder (F150–F240)

Brown Fused Alumina Micro Powder is engineered for ultrafine finishing tasks where precision is paramount. With mesh sizes from F150 to F240, this abrasive powder excels in lapping, polishing, and micro-grinding for ceramics, optics, and metal parts.