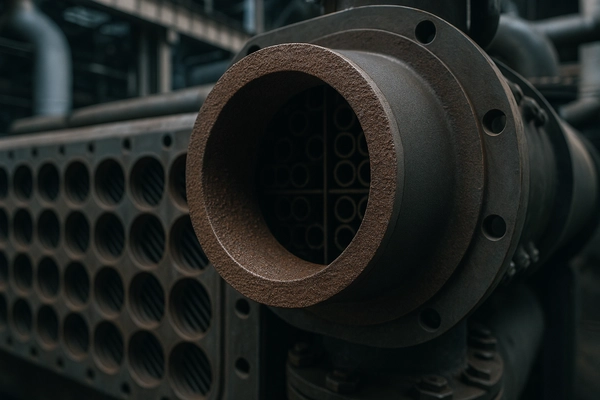

Brown Fused Alumina for Heat Exchangers

Enhance durability and efficiency in heat exchanger components with high-performance alumina media.

Why Use BFA in Heat Exchanger Systems?

Heat exchangers are exposed to extreme temperatures, chemical attack, and particle erosion. Brown fused alumina (BFA) is used in coatings, refractory liners, and composite modules to increase service life and thermal reliability. Its high thermal conductivity and resistance to abrasion make it an ideal reinforcement material.

- Excellent thermal shock resistance above 1800°C

- Resists acid gas corrosion and ash fouling

- Used in both shell-and-tube and regenerative systems

Applications in Heat Exchange Equipment

- Internal ceramic coatings for exhaust gas coolers

- Refractory tiles and liners in recuperative exchangers

- Abrasive-resistant baffles and gas deflectors

- Ceramic matrix composites in air preheaters and boilers

Used in waste-to-energy plants, steel mills, cement kilns, and chemical refineries.

Recommended Grades

- Ceramic coatings: F60–F180 fine grit

- Castable linings: 1–3 mm, 3–5 mm aggregate

- Composite filler: F220–F600 micro powder

Custom surface treatment and sintered bond formulations available for enhanced thermal cycling stability.

Request Technical Data