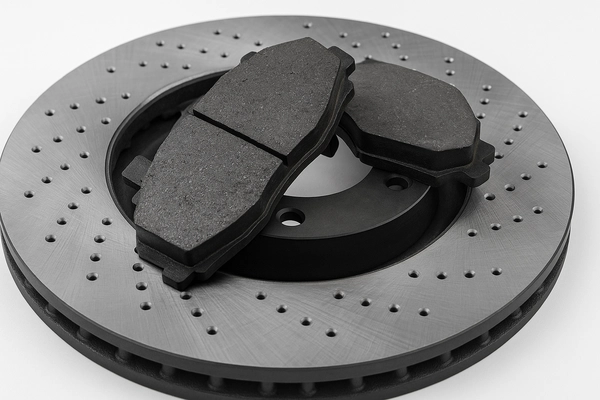

Brown Fused Alumina in Brake Pad Manufacturing

Enhancing durability, friction stability, and thermal resistance in modern brake systems.

Why Use BFA in Brake Pads?

Brown fused alumina (BFA) is widely used as an abrasive filler in the production of brake pads and friction materials. Its high hardness and thermal resistance improve braking consistency, wear resistance, and performance under extreme conditions.

- Improves friction coefficient and thermal conductivity

- Reduces brake fade and increases service life

- Performs well in semi-metallic and ceramic brake formulations

Application in Automotive & Industrial Sectors

BFA is a key component in friction formulations for:

- Passenger car disc and drum brakes

- Commercial vehicle brake linings

- Motorcycle brake pads

- Rail and heavy-duty friction materials

- Industrial press and caliper brakes

- Performance-grade racing brakes

Its role in managing heat, pressure, and wear ensures stable braking in both high-speed and stop-and-go conditions.

Recommended Particle Sizes

For brake pad manufacturing, typical grain sizes used are:

- Macro grit: F24–F80 for structural strength and abrasive contact

- Micro grit: F180–F320 for fine blending and thermal control

Our BFA is available in both grit and powder form, customizable to your friction compound recipe.

Reliable Supply for Friction Manufacturers

CanAbrasive delivers high-purity brown fused alumina that meets the demands of global brake system OEMs and aftermarket suppliers. Our BFA supports consistency in batch production, cost-efficiency, and international compliance.

Request Samples or Technical Data